In May 2015, the State Council issued the “Made in China 2025” notice, which is the action plan for the first ten years of my country’s implementation of the manufacturing power strategy.

The main contradiction of Made in China 2025 lies in intelligent manufacturing.

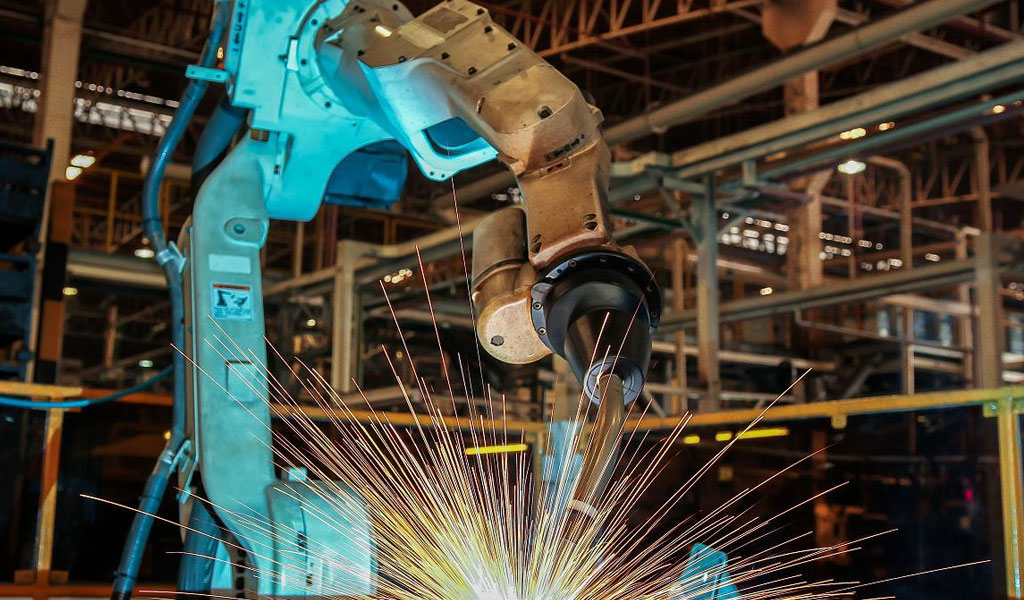

The main contradiction of intelligent manufacturing lies in industrial robots. The main contradiction of industrial robots lies in the upstream core components, especially servo systems, control systems and reducers. Today, ODM WIKI would like to take the reducer as an example to talk about the love and pain of core components made in China. Tracing back to the source, the realization of “Made in China 2025” must first realize the mass production of intelligent industrial robots. However, the core components of industrial robots have become constraints. On the one hand, it is the strong demand for parts and components of “big manufacturing countries”. On the other hand, it is the heavy reliance of the yet-to-be-formed “manufacturing power” on imported parts and components, and the resulting high costs. Among the core components servo system, control system and reducer, the reducer accounts for the largest share of procurement costs (35%). The imports of the three core components accounted for more than 75% of the total purchases.

1. Aizhi reducer: one of the keys to precision manufacturing, the market demand is large and increasing

The reducer is the core component of the robot, which is equivalent to the joints of the human body. It is a sophisticated power transmission mechanism whose main function is to reduce the speed and increase the torque.

my country’s demand for industrial robot parts ranks first in the world, and it is increasing year by year. In 2016, the global sales of industrial robots reached 294,000 units, of which 90,000 units were sold in China, accounting for 30% of the global demand. China Industry Information Network predicts that the sales growth rate of China’s industrial robots will be about 20% from 2017 to 2020, and an average set of industrial robots needs to be equipped with 5 reducers/servo motors and 1 control system. Based on this reasoning, the demand for precision reducers/servo motors for domestic industrial robots in 2020 will be nearly 780,000 sets.

There are two types of precision reducers most commonly used now, RV reducer (60%), and harmonic reducer (15%). These two reducers are monopolized by Japan’s Nabtesco and Hamonica Drive respectively.

The harmonic reducer is suitable for robots under 20 kg. With the increase of use time, the harmonic reducer will have a certain deformation, and its performance will be weakened.

The RV reducer is suitable for robots above 20 kg. Compared with the harmonic reducer, it has better performance, but it is more difficult to manufacture and more expensive.

The principle of RV reducer is more complicated than other types of reducers. It has two-stage transmission device-the first stage involute cylindrical gear planetary reduction mechanism + the second stage cycloidal pin wheel planetary reduction mechanism. The complex structure guarantees its precision and durability.

2. Reducer of pain: high cost of relying on imports, backward technology and difficult mass production

Core components are extremely dependent on imports. Imports of servo systems, control systems and reducers accounted for 80%, 80% and 75% respectively. The bargaining power of domestic enterprises is still weak at present, and the price of purchasing reducers is 2 to 5 times that of foreign enterprises, which eventually causes the cost of reducers in industrial robots to reach 30%.

The key reason for the above phenomenon lies in technology.

The RV reducer adopts an over-positioning structure, which can improve the local stiffness and positioning stability of the workpiece, but at the same time it may cause positioning interference, deformation of the workpiece or positioning components, and increased error. Therefore, the manufacture of RV reducers has very high requirements for machining accuracy and fit, basically at the μm level. The picture below is the various parts of the RV deceleration after its “joint” is disassembled.

Japan’s Nabtesco and Hamonica Drive both started to invest in machine manufacturing research and development around the 1950s, while China’s start was decades behind. In recent years, although some companies have been able to manufacture core components with comparable technical levels, it is difficult to guarantee the service life of the machines. It’s also about precision when building the robot. In order to achieve a perfect matching degree, the Japanese scientific research team has adjusted the material ratio bit by bit in the laboratory, and continuously conducted comparative experiments. To achieve the same level of Chinese technology, first of all, it needs the calmness of the craftsman, and secondly, it needs the accumulation of time. If the accuracy is not suitable, then the robot is more likely to be worn out. Therefore, although domestic robots are comparable to international ones when they leave the factory, their performance will decline after a period of time. In addition, due to the high cost of machine tools for producing core parts, domestic parts have not been fully mass-produced. The profit from selling robots is difficult to cover the investment in procurement costs, and robot manufacturers do not have more funds to inject into technology research and development. As a result, a vicious cycle of “insufficient R&D funds -> technology up to standard -> poor sales -> no mass production -> high manufacturing costs -> insufficient R&D funds” has emerged.

The situation can be even worse. Fascinated by the strong domestic market demand, foreign robot manufacturers have entered China one after another, actively deploying in the Yangtze River Delta. In response to the newly emerging domestic brands, foreign manufacturers have adopted price cuts to further weaken the market competitiveness of domestic robots.

3. A two-pronged approach to policy research and development, see through the red dust and jump out of reincarnation

The support of the national policy for the robot industry can be said to be very good——

In 2012, the “Twelfth Five-Year Plan” National Strategic Emerging Industry Development Plan proposed to focus on the development of “intelligent manufacturing equipment industry”;

In 2013, the Ministry of Industry and Information Technology’s “Guiding Opinions on Promoting the Development of the Industrial Robot Industry” proposed that the development of industrial robots will play an important role;

In 2015, the Ministry of Industry and Information Technology’s “Notice on Carrying out the 2015 Smart Manufacturing Pilot Demonstration Special Action” proposed to invest more than 11 billion yuan in 94 demonstration projects, from policy support to financial support;

2015 “Made in China 2025”, established intelligent manufacturing as the “main direction” of Made in China 2025…

Under the vigorous promotion of policies, robotic machining industrial parks have been planned in many places. However, the number and scale of enterprises in the industrial park are very small, and it is difficult to form agglomeration advantages, and there are phenomena of blindness and redundant construction. The “White Paper on the Development of China’s Robot Industry (2016 Edition)” issued by the CCID Research Institute of the Ministry of Industry and Information Technology puts forward the following five suggestions:

- 1. Improve the policy support system

- 2. Increase technology research and development efforts

- 3. In-depth development of demonstration applications

- 4. Focus on breakthroughs in key products

- 5. Strengthen the construction of talent team

After all, pearls are the accumulation of sand grains over time. Facing the reality of imperfection, and then improving the technology in a sustainable way, without rushing or slacking off, is the shortcut. The path that should be walked has gone, the eons that should have been passed have passed, and you will become a Buddha through cultivation.

Link to this article:Robot Parts Manufacturing In China

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^