In recent years, the world’s manufacturing powers have promoted the transformation of manufacturing to intelligence and automation. In 2016, the Ministry of Industry and Information Technology issued the “Guidelines for the Implementation of Intelligent Manufacturing Engineering (2016-2020)”, hoping that enterprises will bring “two improvements and three reductions” through the implementation of intelligent manufacturing, namely: a substantial increase in production efficiency and comprehensive utilization of resources The rate of production is greatly improved, the development cycle is greatly shortened, the operating cost is greatly reduced, and the product defect rate is greatly reduced.

During the “Thirteenth Five-Year Plan” period, vigorously developing intelligent manufacturing has become a broad consensus among Chinese business circles. A large number of companies have initially solved the problem of low efficiency in traditional manufacturing, and have gradually moved from labor-based repetitive manufacturing to digitization with widespread participation of automated equipment. Manufacturing transformation. The first is to effectively alleviate the problem of insufficient labor in the manufacturing industry; the second is to solve the “blind spots” of enterprises in the production and operation process; the third is to open up the information islands between enterprise research and development, production, and logistics; the fourth is to digitize and digitalize the industry. Industrialization has laid a solid foundation. Especially during the epidemic period, smart manufacturing has given a large number of companies strong vitality and took the lead in resuming work and production. Some companies have adjusted their production lines to process medical supplies such as masks and protective clothing in a timely manner through business transformation and expansion, and solved urgent needs.

There are also some problems in the implementation of intelligent manufacturing. The implementation of intelligent manufacturing by enterprises is easy to “virtualize”, too advanced network construction and deployment, and insufficient attention to the digitalization of the manufacturing process; the pace of digital transformation of the majority of small, medium and micro enterprises is still slow. Insufficient funds and lack of technology have affected the enthusiasm of small, medium and micro enterprises; the supply of intelligent manufacturing talents cannot meet the needs of the next large-scale digital transformation across the country.

The outline of the “14th Five-Year Plan” clearly puts forward the advancement of the advanced industrial base, the modernization of the industrial chain, and the improvement of economic quality, efficiency, and core competitiveness. During the “14th Five-Year Plan” period, to achieve the improvement of manufacturing quality and efficiency, maintain the basic stability of the manufacturing industry, and improve the modernization level of the industrial chain, the key means of intelligent manufacturing is still inseparable.

1.Unify the understanding and strengthen intelligent manufacturing as the main direction of the manufacturing power.

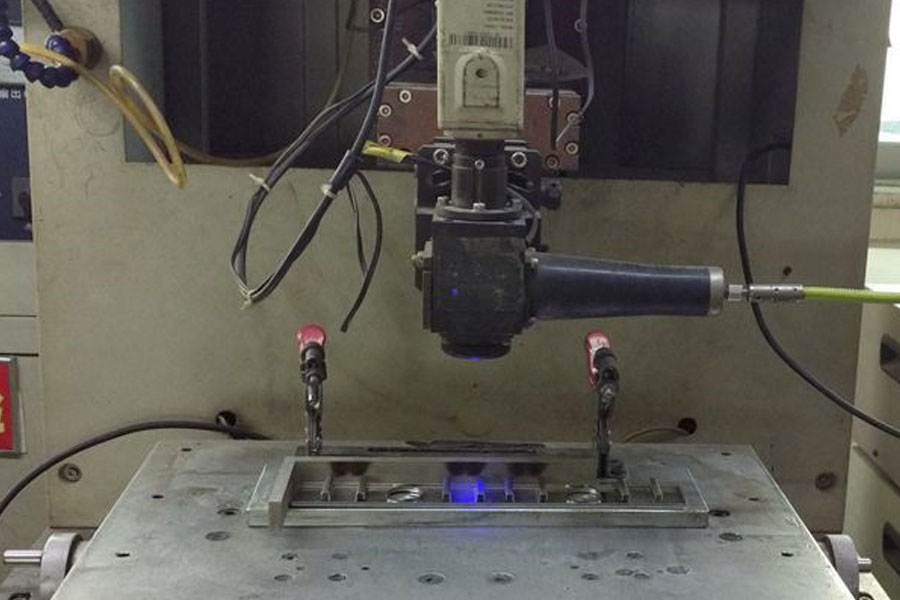

Intelligent manufacturing is an important way for the transformation and upgrading of China’s manufacturing industry and the implementation of high-quality development. On the one hand, it has realized enterprise data collection and data interconnection through digital and networked transformation, improved enterprise manufacturing efficiency, and expanded remote operation and maintenance and customization. New business models and new models such as chemical production have enhanced the core competitiveness of enterprises. At the same time, enterprises have accumulated a large amount of data, which is of great significance to the development of the digital economy. On the other hand, with the continuous integration and deepening of artificial intelligence technology, intelligent manufacturing can solve the problem of Traditional problems such as low product processing accuracy caused by lack of experience have been achieved through the accumulation of data, and the improvement of product processing accuracy has been achieved. At the same time, a batch of smart products have been produced and launched, which promotes products to better meet the growing needs of residents. During the “14th Five-Year Plan” period, more attention should be paid to the role of intelligent manufacturing, attention should be paid to the integration of new-generation information technologies such as industrial Internet and artificial intelligence with manufacturing technology, and industrial Internet and artificial intelligence should be used to improve the efficiency of manufacturing enterprises and achieve a leap in the value chain. The technology means of continuously promoting the development of intelligent manufacturing.

2.Insist on the implementation of intelligent manufacturing by manufacturing enterprises as the mainstay.

The manufacturing industry is the foundation of the nation and the tool for rejuvenating the country. The manufacturing enterprise tax rate is 13%, which is twice that of the financial industry. It is a veritable profit tax operator. Only by effectively increasing the operating income and profit level of the manufacturing industry can the healthy development of the society and economy be promoted. . At the same time, the core of intelligent manufacturing lies in the in-depth application of a new generation of information technology in the manufacturing industry to stimulate new values and new growth points. During the “14th Five-Year Plan” period, the implementation of intelligent manufacturing must avoid “virtualization”, avoid the Internet from representing everything, avoid the “new generation of information technology” that is separated from manufacturing, and provide broad application scenarios for the new generation of information technology through manufacturing. Promote a new generation of information technology that solves practical problems in the manufacturing industry.

3.Pay attention to the intelligent manufacturing of the vast number of small, medium and micro enterprises.

Small and medium-sized enterprises contribute more than 50% of taxes, more than 60% of GDP, about 70% of patented invention rights, and more than 80% of urban labor employment. However, small, medium and micro enterprises are often disadvantaged in fixed asset investment and technological transformation and lack funds. Support and lack of technical support often discourage small, medium and micro enterprises from smart manufacturing. During the “14th Five-Year Plan” period, the implementation of intelligent manufacturing must focus on solving the digital network transformation of small, medium and micro enterprises, and develop low-cost and simplified intelligent equipment and industrial software. Only when the majority of small, medium and micro enterprises move towards digitalization can it represent my country’s move towards intelligence. society.

4.Improve the overall intelligent manufacturing level of the industrial supply chain.

From the perspective of the process of intelligent manufacturing, during the “13th Five-Year Plan” period, most enterprises have carried out stand-alone digitalization, production line digitalization, factory digitalization and enterprise digitalization, and intelligent manufacturing has gradually been promoted in enterprises. During the “14th Five-Year Plan” period, the implementation of intelligent manufacturing should focus on the modernization of the industrial chain, focus on promoting the overall intelligence of several key industrial chain supply chains, improve the efficiency of industrial chain collaborative manufacturing, and encourage leading enterprises in the industrial chain to increase the industrial chain With regard to technology penetration, network penetration, and data penetration of the supply chain system, leading companies should assist upstream, midstream, and downstream companies in the industry chain to implement smart manufacturing in accordance with unified standards, and promote the orderly flow of smart manufacturing talents in the industry chain.

5.Colleges and universities should play a greater role.

At present, the application of robots and CNC machine tools has basically solved the problem of insufficient supply of skilled personnel, and the majority of enterprises can get rid of their dependence on labor through “unmanned factories”. However, “unmanned factory” is not equal to “zero-man factory”. The number of skilled robots and CNC machine tool operators and maintenance personnel required by enterprises, as well as the personnel who master information technology, has increased significantly, that is, more technical personnel are needed. These technical personnel are both To understand manufacturing technology, but also to understand information technology, the training of these talents must rely on undergraduates and postgraduates cultivated by institutions of higher learning. During the “14th Five-Year Plan” period, the implementation of intelligent manufacturing must pay close attention to the training of intelligent manufacturing professional and technical personnel, encourage universities to open intelligent manufacturing related majors, encourage enterprises and universities to jointly formulate training programs and jointly set up courses to solve the problem of shortage of technical talents in the future.

Link to this article:Smart Manufacturing Promote The Digital Transformation Of The Industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D Printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D Printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Smart Manufacturing Promote The Digital Transformation Of The Industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^