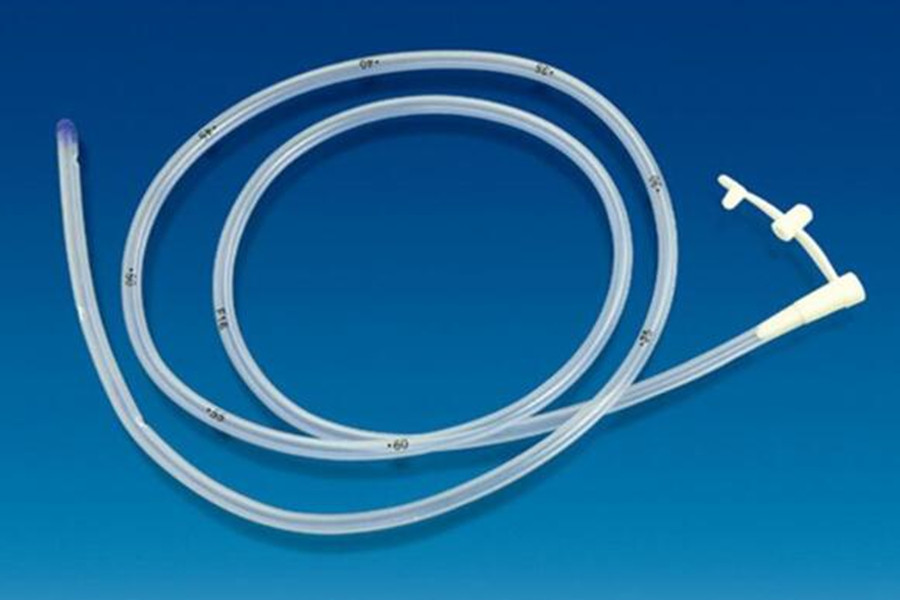

The high capacity and unique recyclability of PVC indicate that hospitals should start with PVC for plastic medical device recycling programs. Almost 30% of plastic medical devices are made of PVC, which makes this material the most commonly used polymer for making bags, tubes, masks and other disposable medical devices.

The remaining share is divided among 10 different polymers. This is one of the main findings of a new market research conducted by Global Market Insights, a global market research and management consulting company. The study also predicts that PVC will maintain its number one position until at least 2027.

PVC is easy to recycle and has a wide range of uses. Equipment that requires soft and rigid parts can be made entirely of one polymer-this is the key to the success of plastic recycling.

The high capacity and unique recyclability of PVC indicate that hospitals should start with this plastic material when considering recycling plans for medical plastic waste.

Ole Grøndahl Hansen, Project Manager of the PVCMed Alliance, commented on the new findings: “The COVID-19 epidemic highlights the key role played by disposable plastic medical devices in preventing and controlling hospital infections. The negative impact of this success is the growing number of hospital plastics. Garbage. We believe recycling is part of the solution. Fortunately, the most used plastic in healthcare is also the most recyclable plastic, so we urge hospitals to start using PVC for recycling activities.”

So far, the existence of CMR (carcinogenic, mutagenic, reproductive toxicity) substances in certain PVC equipment has been an obstacle to medical PVC recycling. According to Ole Grøndahl Hansen, this challenge has now been resolved: “For almost all applications, alternative plasticizers for PVC are available and in use. Four of them are now listed in the European Pharmacopoeia, which is the European and other regions Of medical products have developed safety and quality guidelines.”

Since the establishment of the RecoMed recycling program in the United Kingdom in 2014, the European PVC industry has used VinylPlus to invest in recycling PVC medical devices. The plan was inspired by the successful PVC hospital recycling projects in Australia and New Zealand, which involved more than 250 hospitals.

In February 2021, VinylPlus launched a collaborative project called VinylPlus Med. The project aims to accelerate the sustainability of healthcare throughout Europe by recycling discarded disposable PVC medical equipment. The project brings together hospitals, waste managers, recyclers and the PVC industry in selected European countries.

The plan will focus on the production of PVC recyclates that do not contain worrying substances that can be included in various valuable products sold in Europe. Belgium was selected as the pilot country, with European hospitals, Renewi (waste management company) and Raff Plastics (recyclers) as partners. Other European countries are establishing additional plans.

Link to this article: PVC plastic medical devices become the key to plastic recycling

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:PVC plastic medical devices become the key to plastic recycling

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^