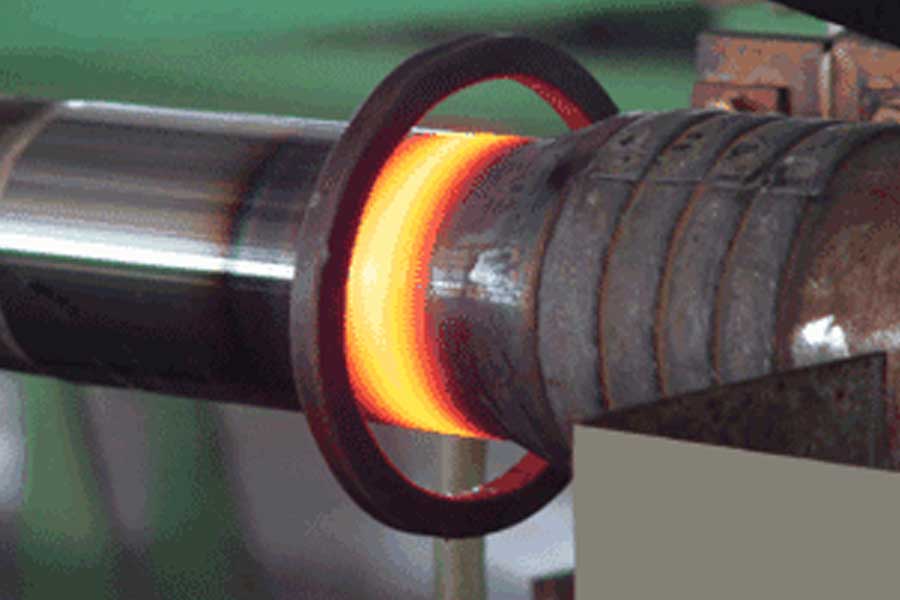

Surface heat treatment is a metal heat treatment process that changes the mechanical properties of the surface layer by heating and cooling the surface of the steel part.

Heating during the heat treatment is one of the methods. In this process, improper heating may cause the following defects:

①Defects caused by the change of the chemical state of the outer layer of the blank due to the influence of the medium, such as oxidation, decarburization, carburization and sulphurization, copper infiltration, etc.

② Defects caused by abnormal changes in the internal organization structure, such as overheating, overburning and underheating.

③As the temperature is unevenly distributed inside the blank, the internal stress (such as temperature stress, structural stress) is too large and the blank is cracked. Here are some of the common defects, and the rest can be seen in related examples.

1. Decarbonization

Decarburization refers to the phenomenon that the carbon of the surface layer of the metal is oxidized at high temperature, so that the carbon content of the surface layer is significantly lower than that of the inside.

The depth of the decarburization layer is related to the composition of the steel, the composition of the furnace gas, the temperature and the holding time at this temperature. Heating with an oxidizing atmosphere is prone to decarburization, high-carbon steel is easy to decarburize, and steel with high silicon content is also easy to decarburize.

Decarburization reduces the strength and fatigue performance of parts and weakens wear resistance.

2. Increase carbon

The forgings heated by the oil furnace often have carbon increase on the surface or part of the surface. Sometimes the thickness of the carburized layer is 1.5~1.6mm, the carbon content of the carburized layer is about 1% (mass fraction), and the carbon content of local points even exceeds 2% (mass fraction), resulting in a ledeburite structure.

This is mainly in the case of oil furnace heating, when the position of the billet is close to the oil furnace nozzle or in the area where the two nozzles intersect the fuel, because the oil and air are not mixed well, the combustion is not complete, and the result is A reductive carburizing atmosphere is formed on the surface of the blank, thereby producing the effect of surface carburization.

Carburization deteriorates the machining performance of forgings, and it is easy to hit the knife during cutting.

3. Overheating

Overheating refers to the phenomenon that the heating temperature of the metal blank is too high, or the residence time is too long within the specified forging and heat treatment temperature range, or the temperature rise is too high due to the thermal effect.

Carbon steel (hypoeutectoid or hypereutectoid steel) often appears Widmanstatten structure after overheating. After martensitic steel is overheated, intragranular texture often appears, and tool and die steels are often characterized by a carbide hornification to determine the superheated structure. After the titanium alloy is overheated, there are obvious β-phase grain boundaries and a straight and slender Widmanstatten structure. After the alloy steel is overheated, there will be a stone-shaped fracture or a strip-shaped fracture. The overheated structure, due to the coarse grains, will cause the mechanical properties to decrease, especially the impact toughness.

After normal heat treatment (normalizing, quenching) of general overheated structural steel, the structure can be improved, and the performance will be restored. This overheating is often called unstable overheating; while the severe overheating of alloy structural steel is normalized (Including high temperature normalizing), annealing or quenching treatment, the overheated structure can not be completely eliminated, this kind of overheating is often called stable overheating.

4. Overburn

Overburning refers to the fact that the heating temperature of the metal billet is too high or the residence time in the high-temperature heating zone is too long. The eutectic of the fusible oxide is destroyed, the connection between the crystal grains is destroyed, and the plasticity of the material is drastically reduced. The severely burned metal will crack with a single blow when it is thickened, and transverse cracks will appear in the burned area when it is drawn out.

There is no strict temperature boundary between overheating and overheating. Generally, the overburning is judged by the appearance of oxidation and melting of the crystal grains. For carbon steel, the grain boundary melts during overburning, and when the tool steel (high-speed steel, Cr12 steel, etc.) is overburned, the grain boundary melts and the herringbone-like ledeburite appears. When the aluminum alloy is overburned, the grain boundary melting triangle area and the remelting ball appear. After forgings are over-burned, they are often irreparable and have to be scrapped.

5. Heating cracks

When heating large steel ingots with large cross-sectional dimensions and high-alloy steel and high-temperature alloy billets with poor thermal conductivity, if the heating speed is too fast in the low temperature stage, the billet will generate large thermal stress due to the large temperature difference between the inside and the outside. In addition, at this time, the blank has poor plasticity due to low temperature. If the value of thermal stress exceeds the strength limit of the blank, heating cracks radiating from the center to the periphery will be generated, causing the entire section to crack.

6, copper brittle

Copper brittleness is cracked on the surface of the forging. When observed at high magnification, light yellow copper (or copper solid solution) is distributed along the grain boundary.

When the billet is heated, if the copper oxide scraps remain in the furnace, the steel oxide is reduced to free copper at high temperatures, and the molten steel atoms expand along the austenite grain boundaries, weakening the connection between the grains. In addition, when the copper content in steel is high [>2% (mass fraction)], if heating in an oxidizing atmosphere, a copper-rich layer will be formed under the iron oxide scale, which will also cause steel embrittlement.

Link to this article: Failure analysis in the heating process of thermal surface treatment

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D Printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D Printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Failure analysis in the heating process of thermal surface treatment

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^