In every industry, products are being designed, redesigned or re-evaluated to obtain better materials or functions. The final product consists of many components, which need to be combined in some way. One of these connection methods is laser welding.

Laser welding uses a high-intensity beam to create a molten weld pool to fuse materials together. This is a non-contact process. Compared with other fusion processes, the heat input is low, the processing speed is high, and a deep melting zone can be produced in one pass.

Of course, in order to take full advantage of all these benefits and ensure a high-quality, repeatable process, manufacturers need to consider the advantages of laser welding compared to other fusion welding processes. Joint and fixture design also play a role. As with any metal manufacturing technology, wise implementation begins with a full understanding of the basic principles of the process.

Laser welding 101

The beam used in laser welding is focused to a small spot on the workpiece. The light generated from some form of medium is emitted from the laser source and begins to diverge. Then collimate it so that the beam is parallel and does not grow. The distance from the exit to the collimation surface is called the collimation length. The beam remains collimated until it hits the focusing surface. Then, the beam narrows into an hourglass shape until it is focused at its smallest point. The distance from the focal surface to the smallest point is called the focal length. The size of the focus is determined by the following formula: fiber diameter×focal length/collimation length=focus diameter

The distance with the focal diameter within 86% of the focal area is called the focal depth. If the focus position moves outside the area, the expected processing result will change. The greater the ratio of the focal length to the collimation length, the greater the depth of focus for a given fiber.

Compared with a smaller fiber diameter, a larger fiber has a larger depth of focus. Larger ratios and fibers have a larger spot size, which results in a decrease in power density and therefore a decrease in penetration.

There are two forms of laser welding: thermal conduction welding and keyhole welding. In thermal conduction welding, a laser beam melts the mating parts along a common joint, and the molten material flows together and solidifies to form a weld. For thermal conduction welding of thin-walled parts, pulsed or continuous wave solid-state lasers are used.

In thermal conduction welding, energy is only coupled into the workpiece through thermal conduction. Therefore, the welding depth range is only a few tenths of a millimeter to 1 millimeter. The thermal conductivity of the material limits the maximum welding depth, and the welding width is always greater than its depth. Thermal laser welding is used for fillet welding on the visible surface of equipment housings and other applications in electronic products.

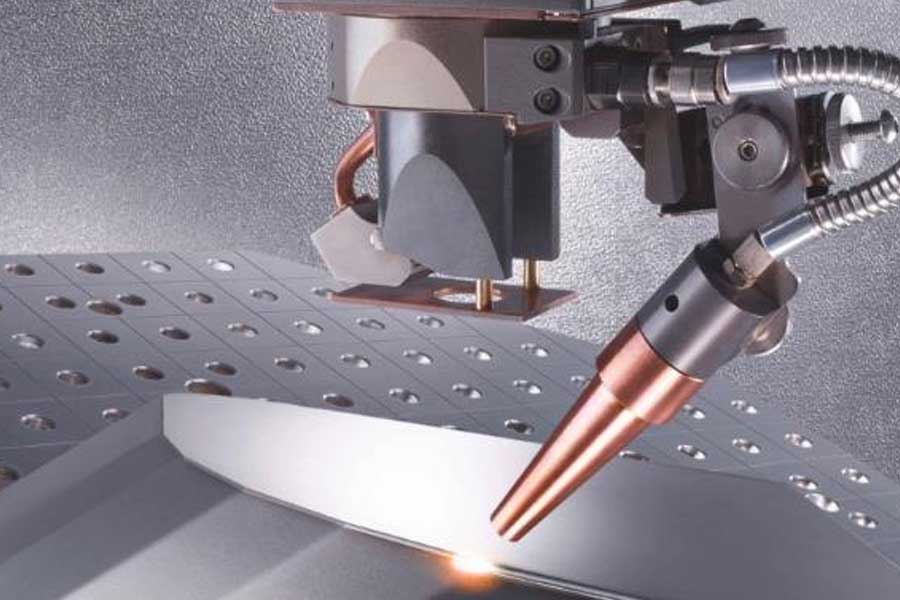

Keyhole welding (see Figure 1) requires extremely high power density, about 1 megawatt per square centimeter. It is used in applications that require deep welding or where several layers of material must be welded at the same time.

In this process, the laser beam not only melts the metal, but also generates steam. The emitted vapor exerts pressure on the molten metal and partially replaces it. At the same time, the material continues to melt. The result is a deep, narrow, steam-filled hole or keyhole, surrounded by molten metal.

As the laser beam advances along the welded joint, the keyhole moves with it through the workpiece. The molten metal flows around the small holes and solidifies in the small holes. This produces a deep and narrow weld with a uniform internal structure. The welding depth may exceed 10 times the welding width. The molten material almost completely absorbs the laser beam, thereby increasing the efficiency of the welding process. The vapor in the keyhole also absorbs the laser light and is partially ionized. This results in the formation of a plasma, which also injects energy into the workpiece. As a result, deep penetration welding is characterized by high efficiency and fast welding speed. Thanks to the high speed, the heat-affected zone (HAZ) is small and the deformation is minimal.

Welding comparison

Compared with other processes, laser welding can provide the highest welding quality, the lowest heat input and the highest penetration in one pass. It has one of the highest range of material combinations and part geometries, has extremely high controllability and repeatability, and is the easiest to automate (see Figure 2). All of these allow for new joint designs, and there is less post-welding processing of parts, which can increase productivity.

Laser welding also has one of the highest initial investment, tool cost and welding joint assembly requirements. These factors must be considered when selecting laser welding as the connection method of the production process.

Joint consideration

Deep penetration welding allows a single weld to replace multiple welds in different joint designs. Some typical laser welded joint configurations are shown. Butt welds do not need chamfering to process thicker parts, T-joints can be welded with full strength from one side, and lap welds can be welded through the top plate or the seam. This provides flexibility in designing parts and welding positions.

Butt welding requires high position accuracy. The typical solder joint diameter is 50 to 900 µm. The allowable position tolerance must be less than half of the beam diameter to ensure that the laser beam interacts with both sides of the joint. The allowable gap is usually 10% of the thinnest material or less than 50% of the diameter of the welded beam. Therefore, clamps are essential in these joint configurations to ensure high position repeatability and minimal clearance.

The common method to solve this problem is to design the parts to be press-fitted or design a sturdy fixture. Some people may use a vision system to ensure part positioning, but this will increase the cycle time and complexity of the production process. It is also important to choose the correct spot size on the part. Larger solder joint size can adapt to larger changes, but requires more energy input to achieve the same weld penetration.

Butt welding has many advantages. The welding strength is determined by the amount of welding along the seam, so the penetration determines the welding strength. Narrow and deep welds generate less heat, thereby creating a smaller heat-affected zone and limiting deformation. Since there is no need to overlap, material consumption can also be reduced.

There are many different considerations for lap welding. The allowable gap is usually 10% of the thickness of the top material. The width of the weld and the fusion at the interface between the two materials determine the strength of the weld. Compared with butt joints, this lap joint configuration results in higher energy input, larger heat affected zone and greater deformation.

If the welding passes through the top plate (3 in Figure 2), the laser beam must penetrate the top plate and enter the bottom plate, and all the energy spent penetrating the top plate will not increase the welding strength. The lap weld must be wider to increase strength. This requires more energy input, which can be achieved by a larger spot size or by oscillation of a smaller spot size. If minimal deformation is critical, the weld should only partially penetrate the bottom plate. If the application requires low heat input, low power or high processing speed, it is ideal to have a partial penetration joint. They create a surface that is not affected by heat input on the back of the weld, and therefore become a Class A surface.

For partially penetrated welds, for thinner materials, the minimum penetration rate into the backsheet should be between 20% and 50%, and for thicker materials, it should be 0.5 mm to ensure repeatable fusion, thereby solving production The difference. The simplest design for welding is to use the thinnest material on the top and thicker material on the bottom. If the top plate is thick, it is difficult to control the penetration of the part into the bottom plate, which also makes it difficult to maintain a Class A surface on the back of the weld.

Joint visits and post-processing

Laser welding can also access joints that were not possible before. Since this is a non-contact process, if the focused beam width is considered, welding can be performed in holes and narrow spaces. This allows flexible joint design and allows less material to be used to design parts.

Because the heat-affected zone of laser welding is small and the total heat input is low, post-weld heat treatment is not required in many cases. After welding, there are almost no weld protrusions on the top or back of the weld. The spatter of this process is extremely small, and a clear weld seam can be formed, especially when shielding gas is added. This eliminates the need for extensive post-weld processing and cleaning.

Fixture design considerations

This fixing method is very common in butt welding and edge welding of tubular or rectangular parts. The clamp is very close to the seam and pressure is applied to ensure the smallest gap. There is no tool above the joint that can interact with the welding beam when focusing.

If a shielding gas is required in certain metals (such as titanium) for aesthetic purposes or for metallurgical reasons, this configuration can also provide a gap for the shielding gas nozzle. The clamp must repeatably maintain the joint in the same Z position relative to the beam so that the laser beam is in the same focus position. This is essential to obtain the same power density to ensure repeatable results.

The fixture required for lap welding is not as strong. A typical fixture design is shown. Multiple clamps can ensure correct contact between two pieces over a large area, rather than a long and rigid clamp that holds the entire seam in place. Pneumatic clamps can be used to automatically perform this fixation. In the example, the scanning optics can quickly solder all the necessary joints. The galvanometer (a high-speed mirror inside the welding optics) positions the beam at the welding position and provides all movement for the welding path. This allows a simple robot path.

For particularly critical welds, a single large fixture designed with a welding path can ensure an ideal part assembly. The tools of the fixation method are costly, but they are also very durable and repeatable. Evenly apply a large load on the surface of the part. This fixation is ideal for stamping parts with large changes in surface flatness.

Unleash creativity

As long as all basic variables are considered, laser welding can exert creativity and some degrees of freedom in part design. For example, what spot size is required for a given process? A larger spot size can provide a larger melt area and a larger depth of focus, but it requires more energy to achieve the same welding depth.

Similarly, what is the best joint configuration? Butt welding requires precision and process repeatability, but it can achieve firm welding with minimal heat input. On the contrary, lap welding requires fewer fixtures and a larger processing window, but requires more heat input to achieve stronger welding.

With the consideration of all laser welding processes, it also brings countless opportunities. This is an excellent tool to use innovative and creative part designs to advance manufacturing. It not only improves quality, but also has the potential to significantly reduce costs due to the reduction of manufacturing steps (including less secondary processing).

Link to this article: Analysis of basic precautions for laser welding

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Analysis of basic precautions for laser welding

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^