For mold manufacturers, since the quality of the mold directly determines the efficiency of injection molding production and the quality of the product, which determines the added value of the product, how to efficiently cool plastic products in the minimum cycle time becomes a conformal cooling mold design and manufacturing A key consideration in the process, and cooling plays an important role in this.

1. Conformal cooling to get rid of the constraints of traditional methods

The principle of conformal cooling is to rapidly reduce the temperature of the plastic part in a uniform and continuous manner. The injection molded part cannot be removed from the mold during the cooling process until the cooling is sufficient, and then the injection molded part is removed from the mold. Any hot spots will delay the injection cycle of the injection molded part, which may cause warpage and depression of the injection molded part after demolding, and may damage the surface quality of the plastic part.

Rapid cooling is through the passage of cooling fluid in the mold to take away the heat of the injection molded part. The speed and uniformity of this cooling effect are determined by the fluid passage and the speed of the cooling fluid passing through it.

The cooling channel in the traditional mold is realized by secondary processing. Through cross-drilling, the internal network of straight pipes is generated, and the flow rate and direction are adjusted through the built-in fluid plug. This method has its limitations. The shape of the water network is limited. Therefore, the cooling channel is far away from the surface of the mold to make cooling low efficiency. Not only that, but also had to face additional processing and assembly time, as well as the risk of blind spot channel network may be blocked. Moreover, in complex cases, in order to reserve the cooling channel for processing, the mold needs to be cut into several parts to be manufactured, and then spliced into a whole mold, which leads to additional manufacturing links and shortens the mold’s time. life.

The difference between the conformal cooling method and the traditional cooling method is that the shape of the cooling water channel changes with the shape of the injection molded product and is no longer linear, as shown in Figure 1. This kind of cooling water channel solves the problem of inconsistent distance between the traditional cooling water channel and the surface of the mold cavity, and can make the injection molded product be uniformly cooled, and the cooling efficiency is higher.

2. 3D Printing manufacturing

3D printing makes people get rid of the limitation of cross-drilling. Now, the internal channel can be designed to be closer to the cooling surface of the mold, and have smooth corners, faster flow, and increase the efficiency of heat transfer to the coolant; it is also possible to design different cooling circuits according to the cooling requirements, aiming at a consistent speed Perform heat dissipation to promote the uniformity of heat dissipation. The coolant throughput is critical to the cooling rate of the mold. It is necessary to design smooth corners to reduce pressure loss along the channel.

The 3D printing technology of selective melting of metal powder can also be produced in cooling channels as small as 1.4 mm in diameter. One of the beneficial benefits of the powder-laying 3D printing manufacturing technology is that the melting of the powder brings about a slightly textured surface. This textured structure increases the surface area of the cooling contact and brings better heat transfer effects, thereby improving the cooling efficiency and A small turbulent flow in the channel is formed, so as to realize the self-cleaning effect of the channel.

3.The added value of 3D printing to injection molded products

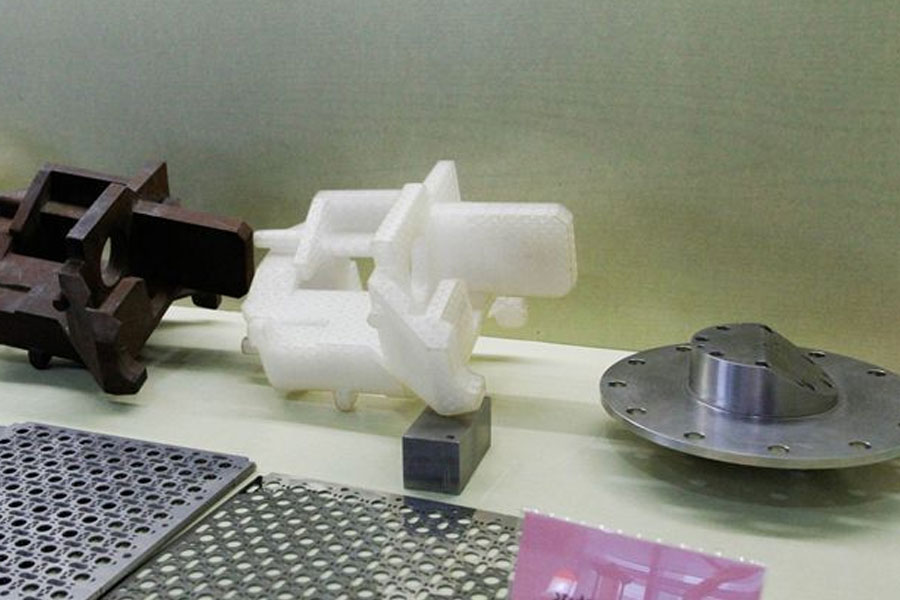

The conformal cooling injection mold manufactured by 3D printing can achieve up to 70% of the injection mold processing efficiency. In the example shown in Figure 2, an ice scraper mold is processed by additive manufacturing, which reduces the injection time from 80 seconds to 40 seconds, which means that the production speed of injection molded parts has doubled.

Other main advantages of conformal cooling molds manufactured by additive manufacturing include: more uniform plastic products can be formed, zero defects in the products, and no shrinkage marks caused by uneven cooling rates. In addition, when developing new injection products, it helps to achieve product development through fewer iterations. Of course, more advantages include when manufacturing complex molds, the additive manufacturing method is faster than traditional methods due to the reduction of cooling channel processing and splicing links.

It should be noted that the surface accuracy of the mold produced by additive manufacturing is not high, and the required surface accuracy must be obtained through post-finishing and polishing treatment. In this link, the advantages of traditional machining and additive manufacturing complement each other.

Link to this article :3D Printing Enhances The Added Value Of Injection Mold Manufacturers

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:3D Printing Enhances The Added Value Of Injection Mold Manufacturers

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^