Measuring workpiece accuracy

| The trial cut method is repeated until the required dimensional accuracy is achieved by “trial cut-measure-adjust-retry cut”. First, try to cut out a small part of the machined surface, measure the size of the test cut, adjust the position of the cutting edge of the tool relative to the workpiece according to the processing requirements, and then test and then measure, so after two or three trial cuts and measurements, when processed After the size is reached, the entire surface to be machined is cut. |

(1) Trial cutting method

First, try to cut out a small part of the machined surface, measure the size of the test cut, adjust the position of the cutting edge of the tool relative to the workpiece according to the processing requirements, and then test and then measure, so after two or three trial cuts and measurements, when processed After the size is reached, the entire surface to be machined is cut.

The trial cut method is repeated until the required dimensional accuracy is achieved by “trial cut-measure-adjust-retry cut”. For example, the test of the box hole system.

The accuracy of the trial cutting method may be very high, it does not require complicated equipment, but this method is time consuming (multiple adjustments, trial cuts, measurements, calculations), low efficiency, dependence on the skill level of the workers and the accuracy of the measuring instruments. The quality is unstable, so it is only used for single-piece small batch production.

As a type of trial-cutting method, it is a method of processing another workpiece that is matched with a workpiece, or a combination of two (or more) workpieces. The requirements for the final size to be machined in the formulation are based on the requirements for the work with the machined part.

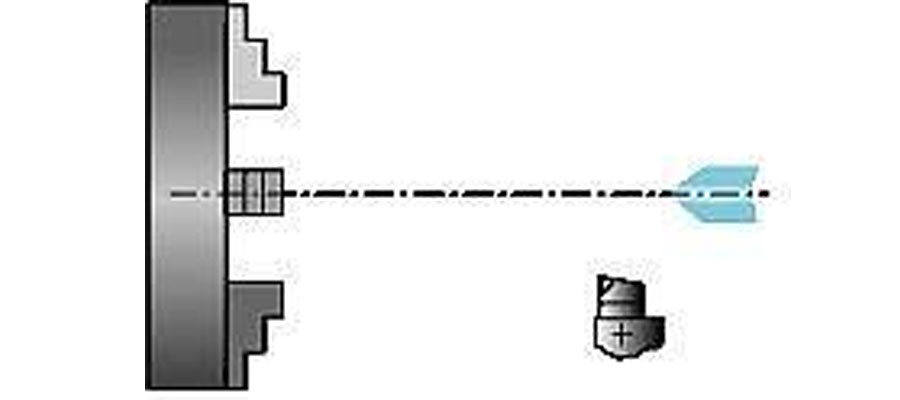

(2) Adjustment method

Precisely adjust the exact relative position of the machine tool, fixture, tool and workpiece with the sample or standard parts to ensure the dimensional accuracy of the workpiece. Because the size is adjusted in advance, the machining time is no longer required, the size is automatically obtained, and it remains unchanged during the processing of a batch of parts. This is the adjustment method. For example, when using a milling machine clamp, the position of the tool is determined by the tool block. The essence of the adjustment method is to use the fixed device or the tool setting device or the pre-finished tool holder on the machine tool to achieve a certain positional accuracy with respect to the machine tool or the fixture, and then process a batch of workpieces.

It is also a kind of adjustment method to feed the knife according to the dial on the machine and then cut it. This method requires the trial cut to determine the scale on the dial. In mass production, the tool setting device such as the fixed stop, sample, and sample is adjusted.

The adjustment method has better processing precision and higher productivity than the trial cutting method, and has low requirements for machine tool operators, but has high requirements for machine tool adjustment workers, and is often used for batch production and mass production.

(3) Fixed size method

The method of ensuring the size of the workpiece to be processed by the corresponding size of the cutter is called a sizing method. It is machined using standard sizes and the dimensions of the machined surface are determined by the size of the tool. That is, tools with a certain dimensional accuracy (such as reamer, reaming drill, drill bit, etc.) are used to ensure the accuracy of the workpiece being machined (such as a hole).

The sizing method is easy to operate, has high productivity, and has stable processing accuracy. It is almost independent of the skill level of the workers, and has high productivity and is widely used in various types of production. For example, drilling, reaming, and the like.

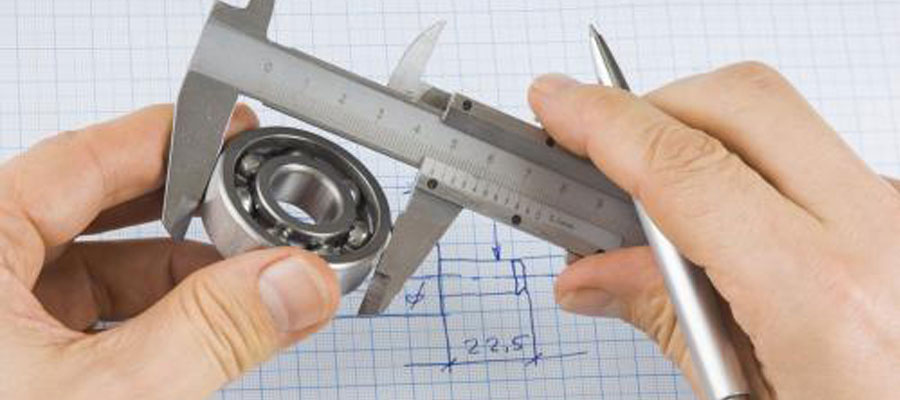

(4) Active measurement method

In the process of machining, the machining dimensions are measured while machining, and the measured results are compared with the dimensions required by the design, or the machine tool is continued to work, or the machine tool is stopped. This is the active measurement method.

Currently, the values in the active measurements are already displayed in numbers. Active measurement adds the measuring device to the process system (ie, the unity of machine tools, tools, fixtures, and workpieces), making it the fifth factor.

The active measurement method is stable in quality and high in productivity, which is the development direction.

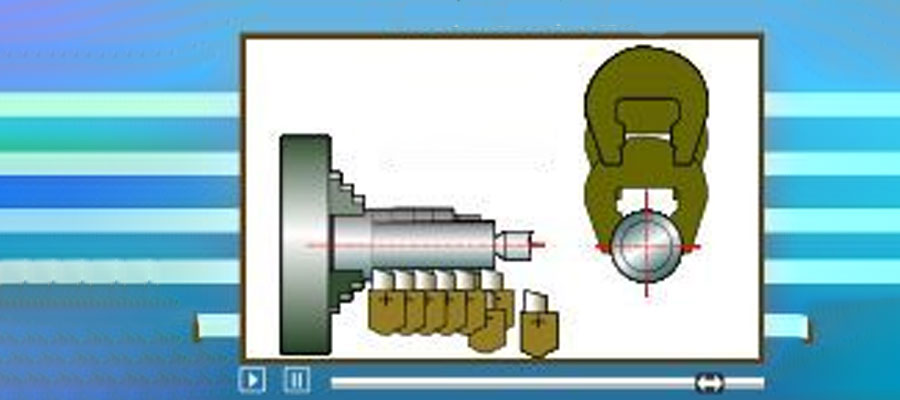

(5) Automatic control method

This method consists of a measuring device, a feed device, a control system, and the like. It consists of an automatic machining system that combines the measuring, feeding and control systems. The machining process is done automatically by the system.

A series of tasks such as dimensional measurement, tool compensation adjustment and cutting, and machine parking are automatically completed to automatically achieve the required dimensional accuracy. For example, when machining on a CNC machine, the parts are controlled by various commands of the program to control the machining sequence and machining accuracy.

There are two specific methods for automatic control:

- 1.Automatic measurement means that the machine has a device for automatically measuring the size of the workpiece. When the workpiece reaches the required size, the measuring device issues a command to automatically retract the machine and stop working.

- 2.Digital control means that there are servo motors, rolling screw nut pairs and complete digital control devices that control the precise movement of the tool holder or table. The size is obtained (movement of the tool post or movement of the table) by pre-programmed procedures. Automatic control by computer numerical control device.

The initial automatic control method was completed using active measurement and control systems such as mechanical or hydraulic. At present, the program pre-programmed according to the processing requirements has been widely used, and the program controlled by the control system to control the machine tool or the digital control machine tool that the digital output information command is issued by the control system, and can adapt to the change of the processing conditions in the processing process, automatically Adjust the amount of processing, and optimize the machining process according to the specified conditions to control the machine tool for automatic control processing.

The automatic control method has stable quality, high productivity, good processing flexibility, and can adapt to multi-variety production. It is the development direction of mechanical manufacturing and the basis of computer-aided manufacturing (CAM).

Link to this article: 5 ways to measure workpiece dimensional accuracy

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:5 ways to measure workpiece dimensional accuracy

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:ODM Wiki,thanks!^^